Home » Applications » Application, Beer (Brewing)

NiGK’s temperature labels are also utilized in the field of beer brewing.

Here, we will briefly introduce the role played by our labels in beer brewing.

Temperature management of beer brewing processes

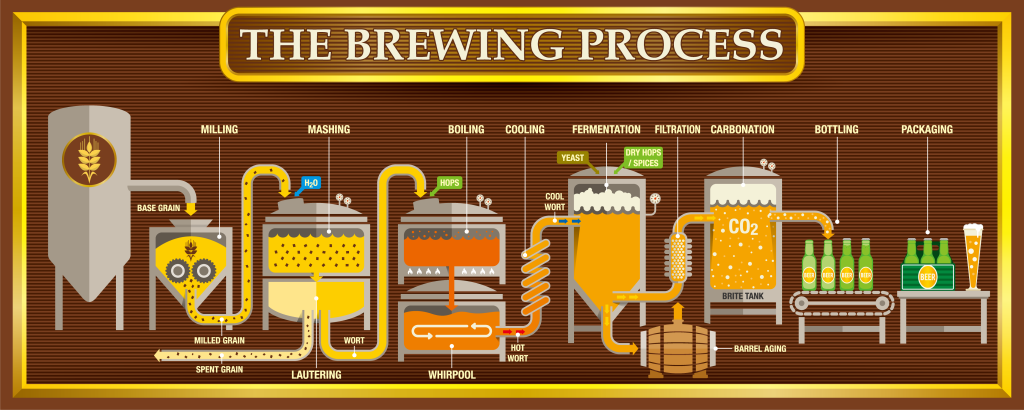

Several processes are involved in making beer including malting, brewing, fermentation, maturation, filtration, and bottling. The brewing process involves saccharifying raw materials to produce wort. This is achieved by gradually raising the temperature of the malt (60-80℃), adding secondary ingredients such as starch, and using enzymes contained in the malt to break down the starch. The activity of the enzymes that play an important role in this process is greatly affected by temperature, and the optimal temperature for the highest activity level depends on the type of enzyme. Therefore, the temperature during this process greatly affects the taste of the beer. In addition, because enzymes are denatured and lose their activity when heated above a certain temperature, thorough temperature control is required. NiGK’s irreversible temperature labels are used as one of the methods of temperature control in these processes, aiming for more precise quality control.

Temperature management during brewing equipment maintenance

The production of beer involves many types of equipment, including preparation tanks, fermentation tanks, and hot and cold-water tanks.

Proper maintenance of these facilities not only extends their lifespan, but also ensures a consistent production of high-quality beer.

For example, cleaning and disinfection of equipment is a necessary process to ensure the safety of the beer produced. During the process of cleaning fermentation tanks and other equipment, the temperature must be above 80°C to achieve the best possible cleaning results. Thus, NiGK’s irreversible temperature labels and indicators for hot water disinfection are also used in the maintenance of equipment where temperature control is critical.

By simply affixing temperature labels, you can check the temperature history of your processes.

NiGK’s labels may also play a part in ensuring the taste and safety of the beer you enjoy this evening.

Our temperature labels are utilized in a variety of fields where heating process is required.

Please feel free to contact us if you are interested.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |