Home » Applications » Application, Plant Equipment

In this example of usage, we will show you how our temperature labels can be used for factory equipment-related management.

First of all, equipment management includes inspection of the production equipment itself, facilities, and buildings to maintain their functions. Especially in the manufacturing industry, the operation and management of machinery and equipment greatly affects the production activities. In recent years, with the increasing use of IT in factories, a great deal of advanced machinery and equipment has been installed in manufacturing sites, making equipment management even more important. In addition, failure to properly implement management of machinery, equipment and facilities may lead to losses due to accidents or breakdowns. Equipment management is a significant matter to be thoroughly worked on not only for the sake of corporate profits but also to ensure the safety of workers at manufacturing sites.

Now, let’s take a look below how “temperature labels,” which have been used by customers in various industries for over 50 years, can contribute to power facility management.

1. Can easily stick to the part of the equipment to be monitored

2. By color change in the label visibly indicates abnormal overheating

3. Irreversible labels can be used to keep a history of abnormal heating

by color change

4. Functions without the need for a power supply, maintenance, or any special

skills

5. Highly durable and can be used indoors for 5 years and outdoors for 3 years

6. Resistant to weather conditions and general factory contaminants

7. User-friendly, cost-effective, and can stick in any locations

*There is a variety of equipment that should be managed.

Temperature label offers easy and reliable temperature control.

*The benefits of temperature labels may provide an effective solution to

on-site problems.

*Examples of temperature labels used in equipment

(1) For control panel (Temperature label inside)

(2) For cubicle

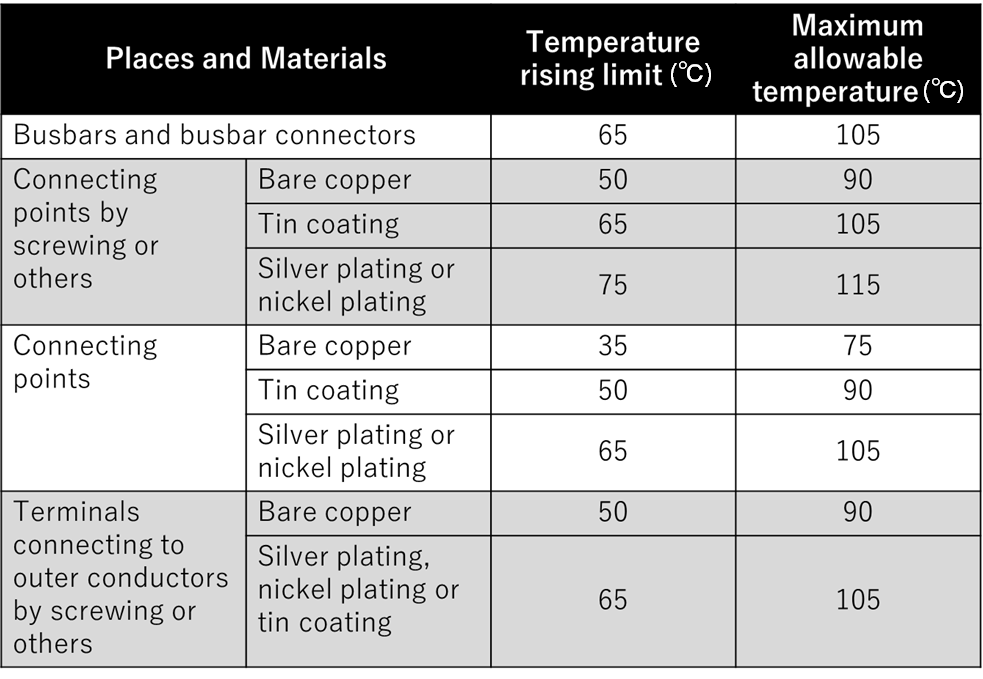

The followings are for your information.

Japanese JIS C 4620: 2018 standards for cubicle type high voltage power

receiving units under 4,000kVA capacity.

This table mentioned each allowable temperature is excerpted from Japanese standards.

(3) For machinery or motors

*We offer a wide range of temperature labels to meet facility management needs.

Whether you want to monitor specific temperatures, need labels of certain sizes, or require heat management for specific applications, we are happy to assist you.

Please feel free to contact us for more information.

*for further details, please press the above picture.

*NiGK is pleased to receive inquiries. Press the bottom below.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |