Home » Temperature / UV Indicator Labels » UV LABEL™/UV LABEL™ for LED

UV labels contribute to monitoring the performance of UV lights

or preserving evidence of irradiation level for quality assurance.

Just paste a UV label indicator wherever you want. “they’re easy to handle, and easy to check”.

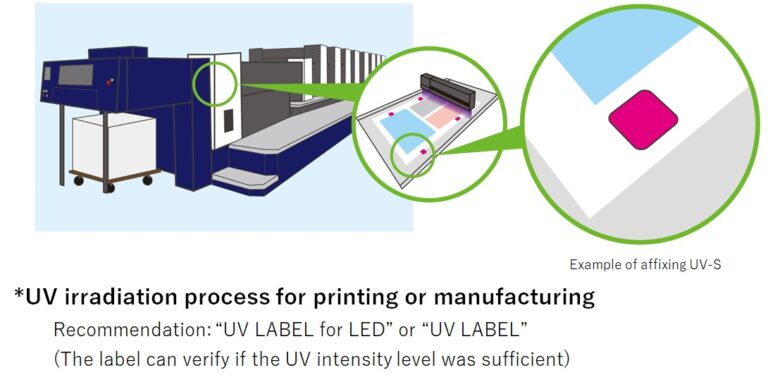

UV labels for use during the manufacturing process

*Curing resin

Micro lenses, precision devices, touch panels, etc.

*Drying inks

Printing, coating for automotive parts, etc.

*Cleaning

Semiconductor manufacturing processes

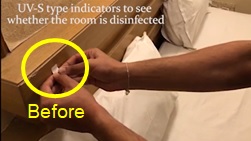

Features of UV labels for disinfection practices

<Features>

*Checking the radiation dose level

*Increasing the reliability of disinfection for

hard-to-access spots.

*Checking the performance of disinfection lamps with limited service life.

With the UV indicator, you can recognize the effectiveness of the UV disinfection system and confirm whether the work has been done completely and reliably.

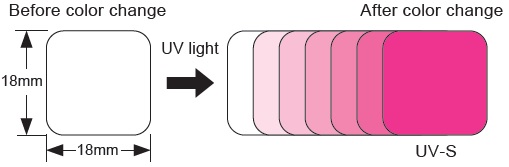

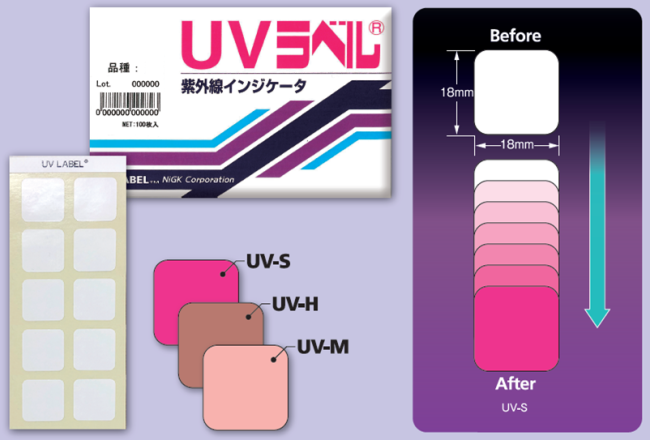

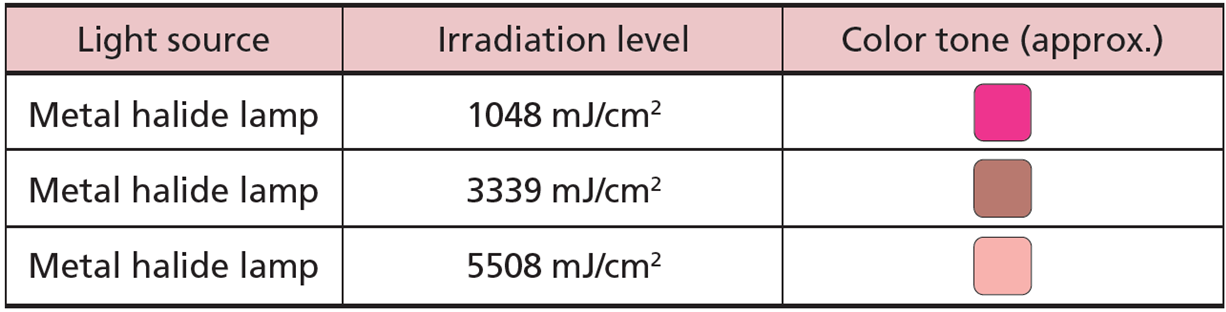

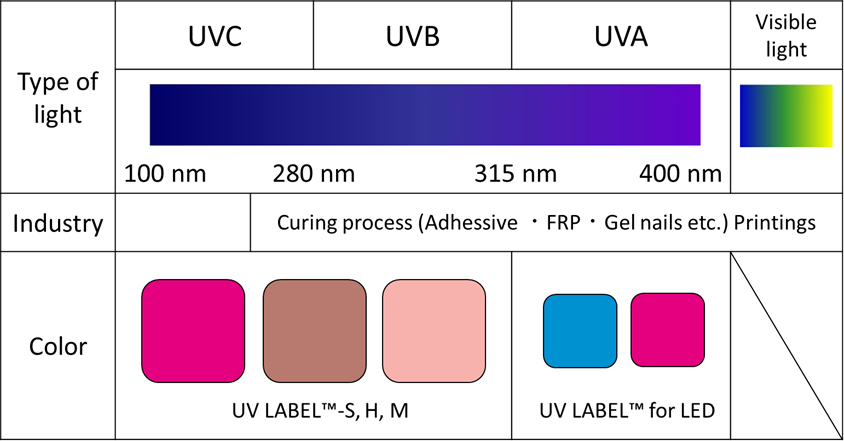

Standard UV label for wide wavelength

Type: UV-S, -H, -M

Number of elements: One

Content: 100pcs/pkg

RoHS compliant

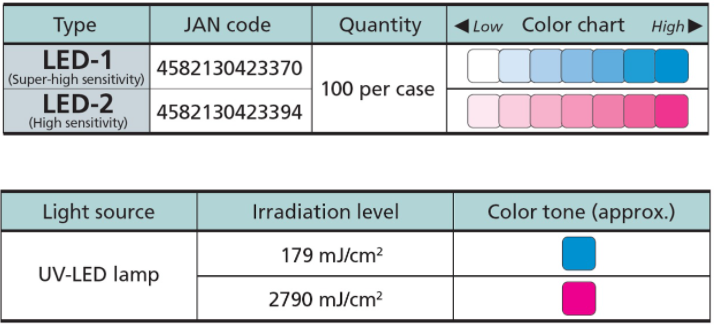

Special label for UVA wavelength

Type: LED-1, -2

Number of elements: One

Content: 100pcs/pkg

RoHS compliant

*The color tones and irradiance levels shown above are based on factory tests conducted using mercury lamps. The color tone and radiation reading may differ depending upon radiation conditions.

*The LED-1 label changes from white to bright blue. There is high sensitivity around UVA ranges 365, 385, 395 and 405 nm.

For more technical information about the UV LABEL™ and UV LABEL for LED, please read the following articles.

Store unused products using the black light-blocking film which comes with the product. Avoid any irradiation

before use. Interior lamps and lighting can cause color changes.

Avoid high temperature and excessive humidity. Store at room temperature.

Colors may fade if the color change is insufficient or if stored in high-temperature conditions after color change.

The UV LABEL and UV LABEL for LED do not contain chemical substances prohibited by the RoHS directive.

Immediate health, physical, and environmental hazards: The environmental properties of this product present a low environmental hazard. This product, when used under reasonable conditions and in accordance with the directions for use, should not present a health hazard. However, use or alteration of the product in a manner not in accordance with the product’s directions for use may affect the performance of the product and present health and safety hazards.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |